- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

12-1

PESTOPACK

One Year and Life-Long Technical Support

Engineers Available to Service Overseas

Water, Juice and other soft drinks

Liquid

Full Automatic

2000-18000 bottles per hour

Soda, carbonated drinks, beverages, soft drinks in pop-top cans

PLC+Touch screen

SUS304

Water purify-Beverage Processing-Bottle blowing-Washing Filling Sealing-Labeling-Packing

Siemens/Schneider/Mitsubishi/AirTac/Delta/Can customized

| Availability: | |

|---|---|

| Quantity: | |

Product Description

Adopting equal pressure and negative pressure filling technology principle in this can filling machine.

The filling valve adopts high-precision mechanical valve, with fast filling speed and high liquid level accuracy. It has a complete CIP cleaning function.

When filling, the mouth of the bottle is sealed, the liquid flows down the bottle wall, prevents the liquid from spilling.

Lifting device can meet filling for different cans.

The gear drive has features of high efficiency, low noise, long life and low maintenance.

The machine adopts stepless frequency conversion speed regulation.

The whole can filling machine is automatically controlled by PLC.

The sealing roller is made of high-hardness alloy quenched, and the sealing curve is precision processed by optical curve grinding to ensure the quality of the sealing and the normal operation of the machine.

No cap no capping. Ensure high performance operation and reduce lid damage.

Lifting device can meet capping for different cans.

Automatic stop when lack of bottle.

All parts in can fillng machine that have direct contact with the beverages are made of high quality stainless steel.

The key electrical components of this can filling machine are from international branded companies.

| Model | 12-1 | 18-4 | 36-6 |

| Capacity(BPH) | 2000 | 9000 | 18000 |

| Bottle size | Dia 50-80mm Height 80-150mm | ||

| Power | 2.2 | 5 | 7.5 |

| Dimension(mm) | 2500*1650*1900mm | 2900&1850*1900mm | 3200*2300*1900mm |

| Weight(kg) | 2000 | 3500 | 5500 |

| Material: | Shape: | Volume: | Filling level : | Bottle diameter: |

PET/Aluminum CAN | Cylinder | 100-1000ml | Liquid level: ±1mm | 50-80 mm |

| Adjustable specifications of the bottle type | Bottle Height:80-150mm | |||

| Customers need to buy additional change-over parts for the different bottles. Filling machine have bottle separating system. | ||||

| Container Label & Control Mode | Packaging system | Palletizing system | ||

| Hot Melt Roll-Fed PVC Shrink Label Full Label/ Half Label OPP labeling Manual / Automatic | Packing system | Min,Spec.6-30 piece/Min | Manual Low position gantry palletizer Robot Palletizer High position gantry palletizer Single Arm Palletizer Manual Palletizer | |

| Manual Film shrinker/ Wrap Around packer/ Carton Packing Machine | 1*2 1*4 2*3 2*4 2*5 2*6 3*4 3*5 3*6 4*4 4*5 4*6 | |||

| User Ambient Conditions | Temperature:-15~50ºC;Humidity:No dew/Filling temperature10-85ºC | |||

| User Electrical Supply Specification | Voltage: 220V/380V415V/480V±5%, 3phase; Frequency: 50HZ/60HZ±1% | |||

Stack Speed: 400/600/800/1200 bottles per minute

Max. carrying capacity /layer: 150kg

Max. carrying capacity /pallet: 1500kg

Max. stack height: 1800mm (Customized)

Installation Power: 12KW-16KW

Air Pressure: ≥04MPa

Power: 220V/380V/415V/480V

Air consumption: 300-600L/Min

Size of the Pallet: According to customer requirement

Suitable beverage types: Colar and lemon.

Mixing ratio range: 3:1 or 6:1

CO2 content: 4 times

Volume: CO2 consumption of about 4m3/h

CO2 supply pressure: 0.8-1Mpa

CO2 Purity: 99.9%

Ethylene glycol solution pressure: 1.0Mpa

Ethylene glycol solution inlet temperature: -2℃

Mainly for cooling and sterilization.

The main parts of the machine are made of stainless steel , the top is designed to be openable for easy maintenance and observation.

Nozzles are manufactured using U.S. technology and spray water evenly.

Conveyor belt adopts Rexnor technology, flat surface with small wear.

Smooth and reliable operation with low energy consumption.

Shrink wrapping machine is mainly used for the industry packages for beverage, foods ,no foods glass, plastic bottles and cans, etc.

The machine can automatic finish bottle in-feeding, bottle formation, convey bottle, feed film to wrap and hot shrink to finish package.

Feeding film is tracked by photoelectrical sensor to ensure the accuracy film length.

PLC control, English and Man-machine interface, operating easy and simple maintain.

FILM SHRINKABLE PACKAGING MACHINE

Film packaging machine collate products and pack them in film.

Function: The conveying belt will feed bottles into the position required, and then when the quantity arrive whole package, for example 12 bottles, 15 bottles, the machine will push the bottles to film wrapping , and then with conveying belt the package will be send to the shrink tunnel , finish the shrink process.

Feature:

1) PLC programmable procedure control system, with colorful touch-screen control panel

2) Bottle entering, Auto unscrambling bottle, Pushing bottle, Heat sealing-Saw cutting, Pressing PE, Shrink, Cooling automa

3) Capacity is adjustable through adjust the convey speed

Company Profile

PESTOPACK is an innovative and dynamic company in the design, manufacturing, maintenance and optimisation of water filling machine, beverage filling machine, carbonated drinks csd filling machine, beer filling machine, oil filling machine, sauce filling machine, household products filling machine, capping machine, labeling machine. We are specialized in liquid filling machinery and packing machinery field over 12 years.

In order to meet the demand for carbonated beverage filling machines that fit seamlessly into existing operations, we have developed a range of can filling machine that is unmatched in reliability, efficiency and cost effectiveness. And, because we understand that every cans filling line has its own unique requirements, each of our glass bottle bottling equipment is customized to the individual needs of our customers.

We place our clients first and custom best can filling solution for them until they are satisfied.

Turnkey Solution

We can supply bottle preform, caps, label rolls with very reasonable price.

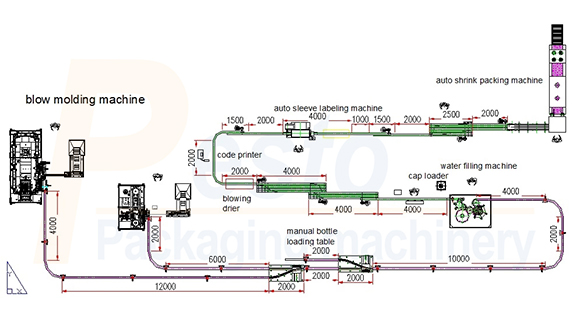

We will design and confirm the machine layout according to your factory sketch.

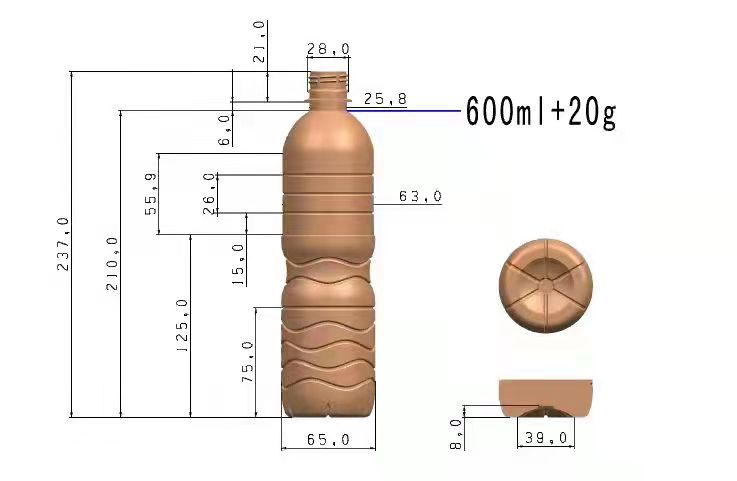

Our designers can design bottle styles according to your requirement.

We can provide the label design according to the bottle size and style you want.

After Sales Service