- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

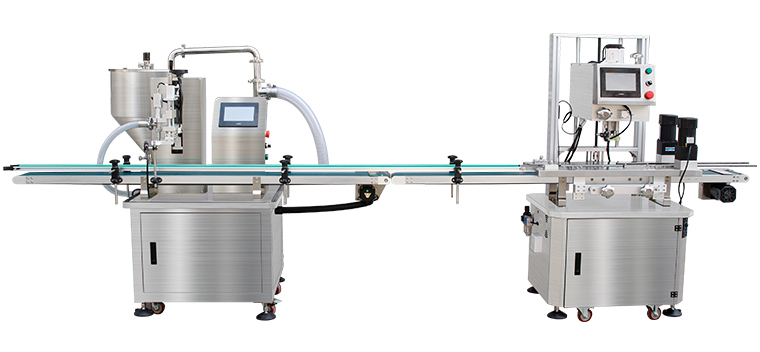

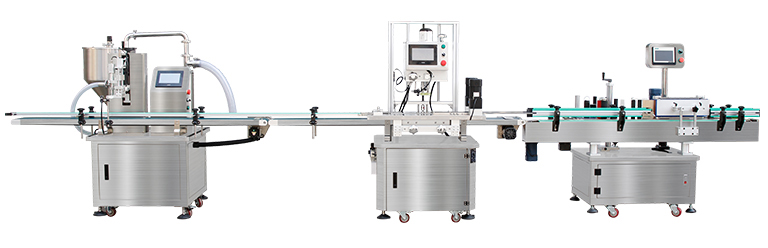

Small Scale Bottle & Liquid Filling Machine

PESTOPACK

One Year and Life-Long Technical Support

Full Automatic

20-80bpm

| Availability: | |

|---|---|

| Quantity: | |

Product Description

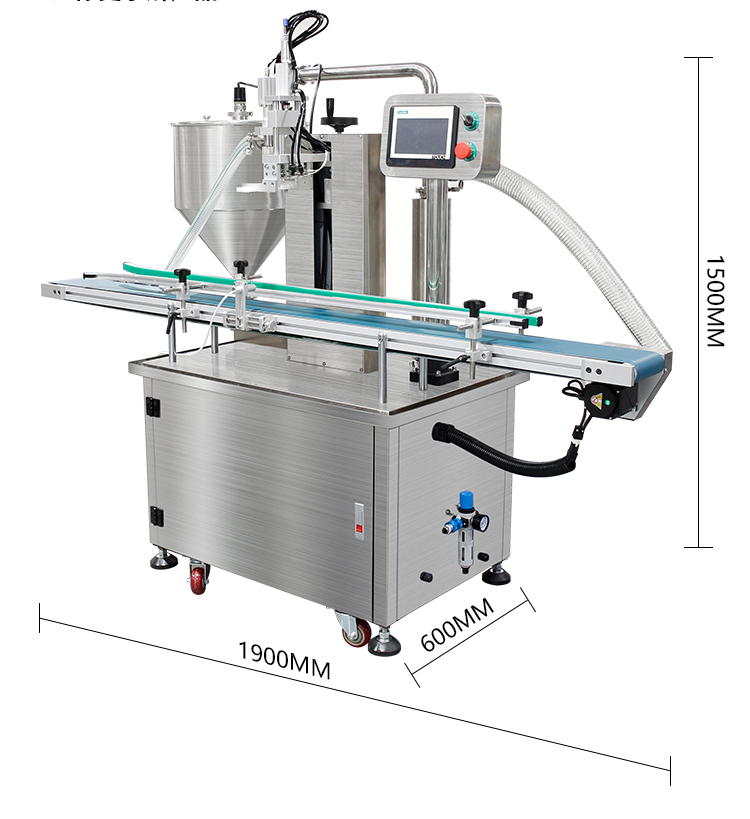

The small scale bottle filling machine is engineered to deliver unparalleled precision and versatility for a variety of filling applications. Powered by advanced servo motors, this small scale bottle filler machine employs a highly accurate gear pump mechanism designed specifically for precise liquid dispensing tasks. The integration of servo technology ensures smooth, consistent, and fast operation, making it ideal for handling both low and high-viscosity liquids with exceptional accuracy.

The small scale bottle filling machine's design focuses on operational efficiency and ease of use, featuring a user-friendly touchscreen interface that allows operators to quickly adjust filling parameters such as volume, speed, and product type. This adaptability makes it suitable for a diverse range of industries, including food and beverages, pharmaceuticals, cosmetics, and specialty chemicals.

Material: Constructed entirely from food grade 304 stainless steel, the small liquid filling machine offers exceptional durability and resistance to corrosion. This material choice not only ensures a long operational life but also complies with strict hygiene and safety standards, making it suitable for handling edible products and sensitive materials.

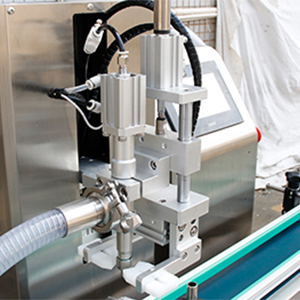

Integrated Suction Pump: The built-in suction pump is designed to optimize the transfer of liquids from storage to the machine. This feature minimizes manual handling, reduces contamination risks, and increases the efficiency of the production process.

Anti-Drip Design: Our innovative anti-drip technology prevents leakage and spillage during the filling process. This design helps to maintain a clean working environment, reduces product loss, and enhances the overall aesthetics of the final product packaging.

Touch Screen Operation: The small liquid filling machine is equipped with an intuitive touchscreen interface that simplifies machine operation. This user-friendly control panel allows operators to easily set up and modify filling parameters, monitor ongoing operations, and troubleshoot issues with immediate visual feedback.

Dual Servo Motor Drive: Powered by two high-performance servo motors, the small liquid filling machine offers superior control over the filling process. These motors provide precise movement and speed adjustments, which are essential for handling different filling volumes and maintaining high throughput rates.

Customization: Understanding that each production line has unique needs, our single nozzle filling machine offers extensive customization options. Clients can tailor aspects such as the filling range and nozzle design to align with specific operational requirements. This flexibility ensures that our machine can adapt to various production environments and evolve with changing business needs.

Brand Components: This single bottle filling system incorporates components from leading global brands, chosen for their proven reliability and effectiveness. These high-quality parts ensure the machine operates flawlessly under continuous use, reducing downtime and maintenance costs, thus enhancing overall productivity.

Anti-drip filling nozzle ensures precise and clean dispensing.

Dual servo motors provide high precision and control.

Constructed from food-grade SUS304 stainless steel for safety and durability.

This small scale bottle filling machine equipped with a 'no bottle, no filling' sensor to prevent spills and waste.

Features a 42L hopper for holding materials.

Movable wheels for easy positioning and transport.

Humanized design includes adjustable speed, adjustable height, and touch screen operation for ease of use.

The small head filling machine includes a loading pump for efficient material transfer.

Anti-drip filling zozzle

Dual servo motors

Food grade SUS304

No bottle no filling

42L hopper

Movable wheels

Filling Range: 5-5000ML

Filling nozzle: 1 (can be customized)

Filling Speed: 20-80 bottles/min (according to liquid viscosity)

Filling Accuracy: ±1% (according to liquid viscosity)

Conveyor Belt Dimensions: 1900*150MM (Length x Width)

Table Height: 790MM (Adjustable by 80MM)

Dimensions: 1900*610*1450MM (Length x Width x Height)

Maximum Load: About 180KG

Material Used: 304 Stainless Steel

Power Specifications: 220V 50HZ 1.8KW

Air Pressure Requirement: 0.5-0.8MPA

Option: Capping, labeling, alunimun sealer, carton sealer

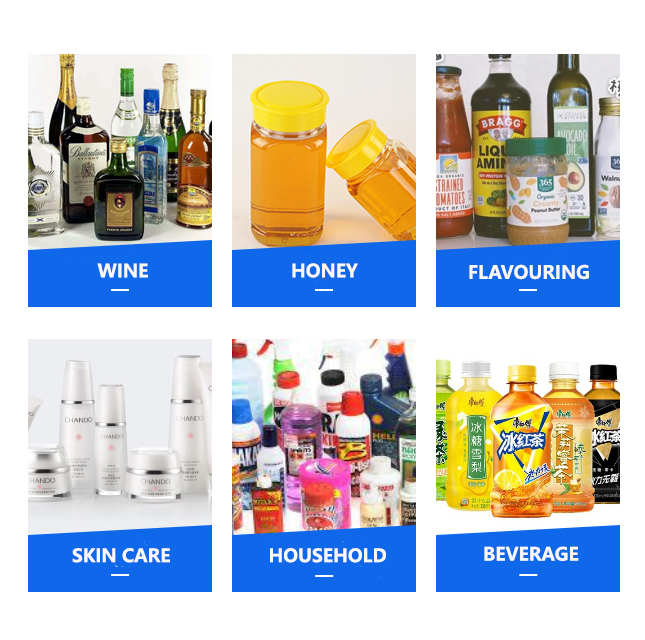

Our versatile small liquid filling machine is designed to handle a diverse range of liquid products, making it an essential piece of equipment for multiple industries.

Here are some specific applications:

Lotions: Perfect for the cosmetics industry, this small filling machine for lotion provides precise filling capabilities for all types of lotions, ensuring consistency and efficiency in production.

Creams: Ideal for both cosmetic and pharmaceutical industries, the small filling machine for creams ensures gentle handling and accurate dosing of various creams, from medicinal to beauty products.

Beverages: This small filling machine for beverages can efficiently manage the filling of non-carbonated beverages, delivering consistent volumes without compromising the integrity of the product.

Honey: Known for its viscosity, honey requires careful handling to maintain its natural properties. Our small filling machine for honey is equipped to fill honey containers with precision, minimizing waste and preserving quality.

Skin Care Products: From serums to gels, our small scale liquid filler for skin care products can accommodate a wide array of skin care formulations, ensuring they are filled accurately and hygienically. Like cream filling machine, we have different solution from small to large scale.

Household Products: This small filling machine for household products is also adept at filling a variety of household products such as cleaning liquids and detergents, supporting the fast-paced production demands of this sector.

Flavourings: Essential for both food production and culinary applications, our small filling machine for flavouring can precisely fill small containers with flavourings, aiding in maintaining flavor consistency across batches.

Sauces: Ideal for food processing, this small filling machine for sauces can handle various types of sauces, including those with particulates. It ensures accurate, consistent fills without altering the texture or integrity of the sauce.

This small liquid filling machine is expertly designed to be integrated into a comprehensive filling line, including options for attachment with filling capping machines and filling capping labeling machines. Its versatile design allows for seamless operation within a broader automated process, enhancing both productivity and efficiency. Ideal for small to medium production volumes, this machine ensures precise filling, followed by secure capping and accurate labeling, providing a complete solution from start to finish. It's the perfect choice for industries looking to streamline their packaging processes while maintaining high standards of quality and accuracy.

Our small liquid filling machine offers exceptional value, combining high-quality performance with affordability. Starting prices for basic models of our automatic small liquid filling machine range from $3,000 to $6,000. These prices can vary based on specific configurations, customizations, and optional features tailored to your unique production needs. For businesses requiring more advanced capabilities, such as integrated capping and labeling systems, prices may increase accordingly.

For detailed pricing information and to get a customized quote that matches your requirements, please contact our sales team. We also offer flexible financing options to help you integrate our technology seamlessly into your production line. Invest in our small liquid filling machine today to enhance your filling operations with precision and efficiency, ensuring a quick return on investment with its durable and reliable performance.

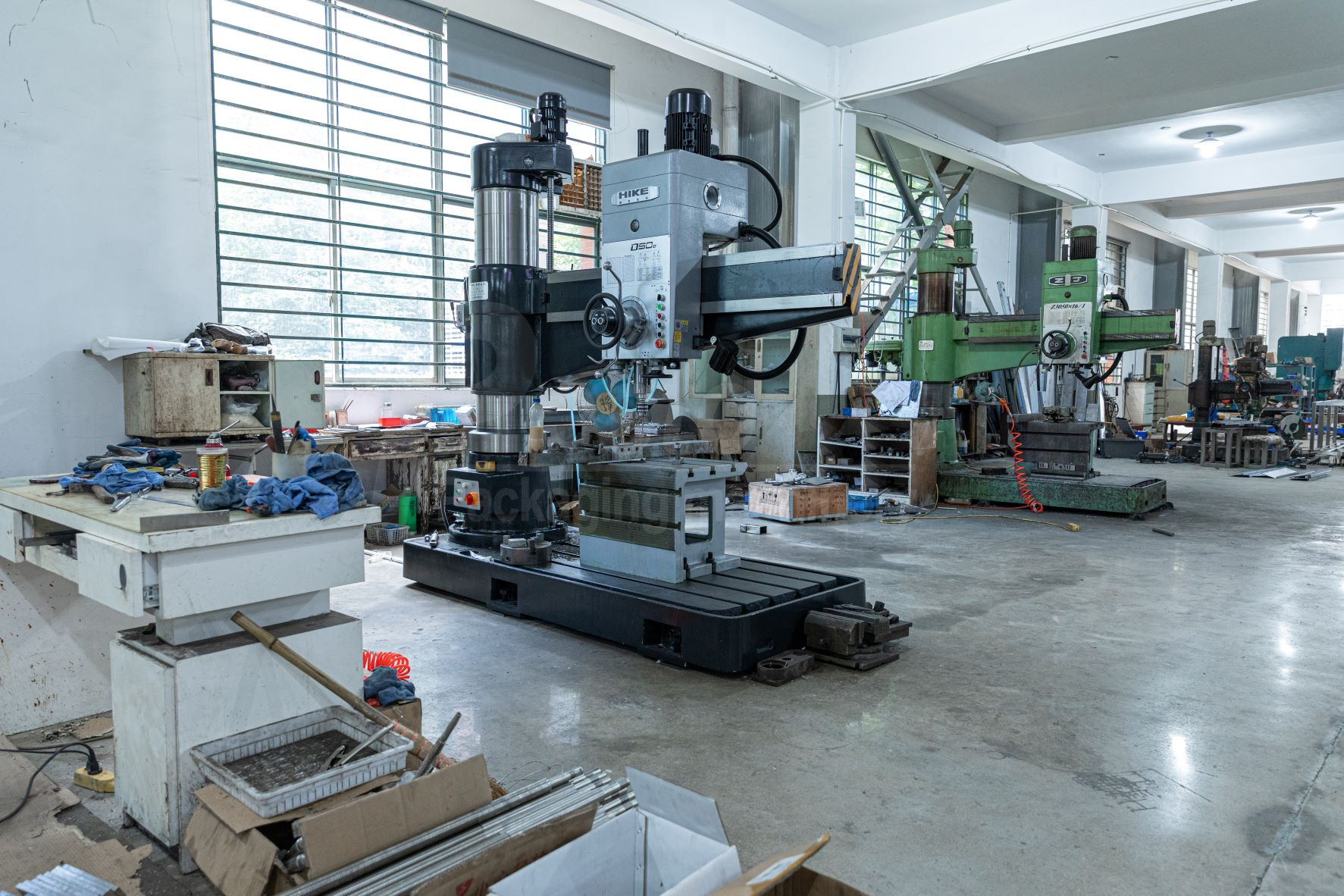

Expertise: With years of experience, our company has developed a profound expertise in manufacturing high-quality liquid bottle filling machines. Our long-standing presence in the industry has equipped us with the knowledge and skills to build machines that not only meet but exceed industry standards. We are committed to continuous improvement and innovation to provide our clients with the best possible solutions.

Customization: Understanding that each liquid production line has its unique challenges, we offer customized solutions tailored specifically to meet your operational needs. Whether it's adapting our liquid filling machines to fit specific space requirements, handling unique materials, or achieving precise filling capacities, our team works closely with you to design and configure the perfect solution for your business.

Support: Our relationship with clients goes beyond the sale. We provide comprehensive after-sales support to ensure your equipment operates smoothly and efficiently. This includes professional installation, thorough training for your staff, and ongoing maintenance services. Our dedicated support team is always ready to assist you with any issues or needs that may arise, ensuring minimal downtime and optimal performance of your machines.

By choosing us, you gain not just a bottle & liquid filling machine supplier, but a reliable partner dedicated to enhancing your operational efficiency and success.